By Yeh Tzu-hao

Translated by Wu Hsiao-ting

One team invented earthquake-resistant furniture, while another created a solar-powered drying system to extend the shelf life of agricultural products. They both identified unsolved problems and devised innovative solutions in their work.

Earthquakes are common in our hometown of Yuli, so we designed this product to increase the chances of rescue,” explained Ye Zhen, an 11th-grader at Yuli High School in Hualien, eastern Taiwan.

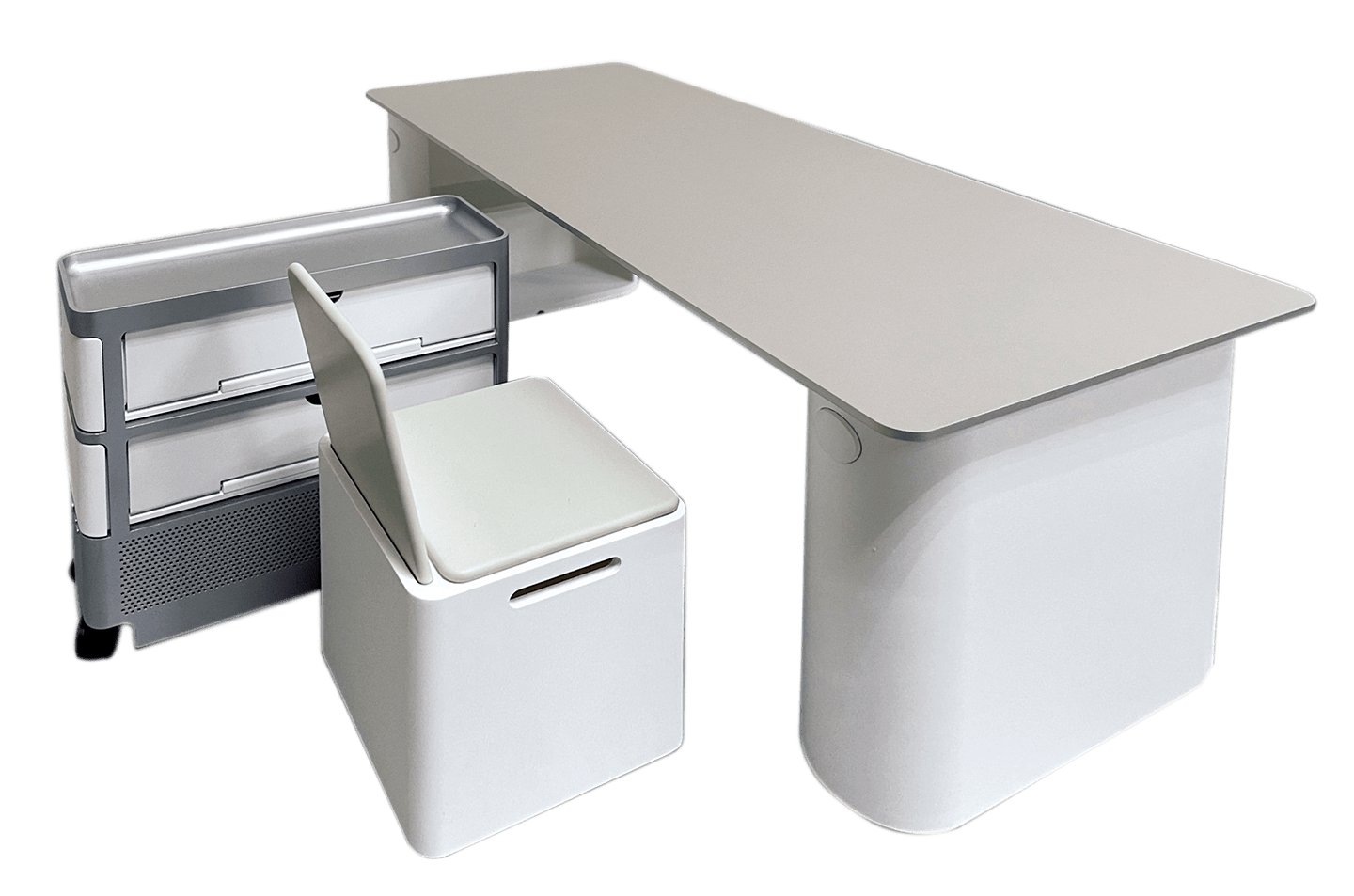

Ye Zhen and her fellow schoolmates, 12th-grader Zhang Zhi-yan and 11th-grader Wu Bo-yi, along with their mentor Xu Qi-rong, formed a team to devise an earthquake-resistant modular furniture set. Their furniture is engineered to withstand the impact of falling objects and building collapse during tremors. The desk and wheeled drawer unit in the set are sturdy, providing space for survival when other indoor furniture would fail. They are also equipped with a built-in LED light, buzzer, and rechargeable battery, which would facilitate rescue operations. Furthermore, the desk and two accompanying chairs offer extra storage space for essential survival supplies.

The team won first place for their design in the high school category at the seventh annual Compassionate Technology Innovation Competition in 2023. One year earlier, the People’s Choice Award went to a solar-powered automatic drying system designed to preserve agricultural products in Indonesia. The Best Application Award that year was won by a team from Keelung Commercial and Industrial Vocational High School in rainy Keelung for their shoe drying machine. These products were created to meet local needs, concretely demonstrating empathy.

Thinking ahead to save lives

Seismic activity is common in Taiwan’s eastern Hualien and Taitung areas, so residents there are familiar with earthquakes. However, many locals, including the Yuli High School team that invented the earthquake-resistant furniture, still harbor lingering fears from the tremor on Sunday, September 18, 2022. When Ye Zhen returned to her school dormitory after the quake, she found herself and her roommates among the victims, with furniture fallen and items scattered everywhere. Zhang Zhi-yan, who was on the second floor of her home during the tremor, quickly rushed downstairs to check on her grandfather’s safety.

The earthquake left such a profound impact that it motivated Ye, Zhang, and their schoolmate Wu Bo-yi to start a project focusing on earthquake response, aimed particularly at aiding the elderly and those with limited mobility. They undertook the project as part of a school course on innovation in practice. Xu Qi-rong, who works in the computer design department of an international corporation in Taipei, became their mentor for the project. The team decided to center their project around earthquake-resistant furniture. They discussed ideas through videoconferences and attended a relevant workshop at the Tzu Chi University of Science and Technology in Hualien on Saturdays and Sundays. Under Xu Qi-rong’s guidance, the three high school students began by sketching and creating paper models, gradually refining their concept step by step. Eventually, they had a professional model maker create a detailed and realistic display model.

Their modular furniture set includes a desk, two chairs, and a wheeled drawer unit. “Our desktop is crafted from an aluminum honeycomb panel made of recycled aluminum, with a weight-bearing capacity four to six times that of a regular desktop,” explained Ye Zhen. Aluminum honeycomb panels are known for their strength and lightness, commonly used in aircraft construction. Ye highlighted other design features of their furniture set: the desktop is not only lightweight and robust but also includes a handle and an LED light on the side facing the floor. One can use the handle for stability when taking shelter under the desk and the LED light automatically illuminates during an earthquake. In ordinary times, the light can serve as a night light.

To bolster resistance, the team used two oval cabinets to support the desk instead of regular desk legs. A built-in electronic timer, set to emit alerts every three or six months, reminds users to check and update the disaster relief supplies stored within the furniture set.

The wheeled drawer unit consists of three tiers. The top two tiers are designed for storing food, medicine, and other emergency supplies. There are small doors on the sides, allowing access to items when necessary without the need to pull out the drawers. The bottom tier is equipped with a buzzer and charging device. In the event of being trapped during a quake, the buzzer provides an alternative to shouting or knocking, helping to conserve energy.

Xu Qi-rong said that they had planned for the worst-case scenario during their design process. In the case of a collapsing roof, their furniture set had to have a certain degree of rigidity to resist being crushed easily and be able to provide a survival space. “Our drawer unit was not originally designed to bear weight,” he explained, “but we deliberately designed it to be close in height to the desktop and capable of bearing weight. If the desktop is deformed under pressure, the drawer unit can be used as support.” The mentor also asserted, “And with supplies around you, the chances of survival will be higher.”

Chen Yan-xing (陳彥杏), Yuli High School’s director of academic affairs, said, “The Tzu Chi University of Science and Technology was wonderful. They provided our students with transportation expenses and equipment to help with their project.” He added that due to their school workload, the three students could often only work on the project during weekends. “Still, they overcame whatever difficulties they encountered and achieved what they set out to do. Both their mentor and I are very impressed!” Chen was happier than the students themselves to see them win first place and two special awards at the Compassionate Technology Innovation Competition.

Xu Qi-rong expressed his pride for the students. He noted that the resources available to them, living in a rural area, were not as abundant as those for students living in cities, and yet the three managed to achieve their “mission impossible” through their own passion for meaningful innovation and their teachers’ enthusiasm for education.

Photos by Liu Wei-xing

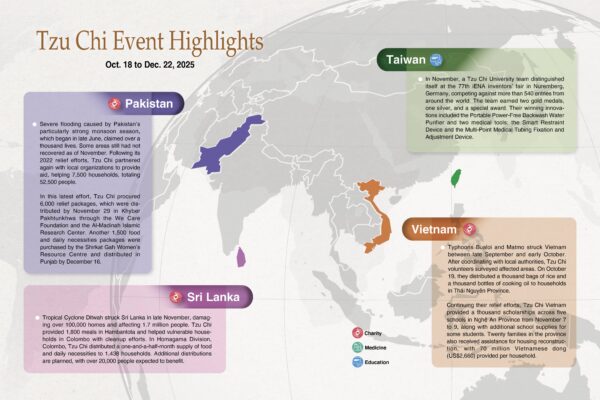

Earthquake-Resistant Modular Furniture Set

● Invention Team

Students from Yuli High School

● Design

The desk and drawer unit in the set are sturdy, capable of providing a survival space during a strong earthquake. They are also outfitted with an LED light, buzzer, and rechargeable battery to increase the chances of rescue in the event of building collapse. The set also includes two chairs with extra storage space for essential survival supplies.

Addressing the issue of surplus produce

While the earthquake-resistant furniture was designed by Taiwanese students, another award-winning invention—the solar-powered automatic drying system—was the brainchild of a group of Indonesian students. These students were from a special class at the Tzu Chi University of Science and Technology. They received scholarships from Indonesia’s Sinar Mas Group to study agricultural production and marketing in Taiwan, aiming to find innovative solutions to challenges facing Indonesia’s agriculture sector.

Bagas Pramana Putra Fadhila, a graduate from this special class, is fluent in Chinese. He explained the reason behind their invention with the help of images on his cell phone. He said that while the quality of the dragon fruit harvested in Indonesia is good, the excessive yield saturates the market, leading to the disposal of the surplus as waste. Chili peppers, essential in Indonesian cuisine, face a similar issue. Bagas hails from the ancient city of Yogyakarta, where his parents run a grocery store. He is most keenly aware of the fluctuating prices of chili peppers in his hometown. “Yogyakarta has many chili pepper farmers,” he said. “Usually, a kilogram of this produce sells for 100,000 rupiah [US$6.37], but during low price periods, it’s only one-tenth of that price.”

Why haven’t Indonesian farmers learned from Taiwan’s farmers’ associations and set up drying centers to address the surplus production issue? It seems simple, but the situation in Indonesia makes such a solution more challenging.

Although Indonesia’s electricity prices are 40 percent less than those in Taiwan, and diesel prices are just half, the income of an average citizen in Indonesia is less than one-sixth that in Taiwan. From this perspective, energy costs in Indonesia are relatively high, making it unviable to dry surplus produce. This explains why, despite being a major chili pepper producer, Indonesia must import large quantities of dried chili peppers from China.

The Indonesian students came up with the idea of using free solar energy to dry excess vegetables and fruits in Indonesia. They created the Solar Thermal Energy Automatic Drying System as their graduation project before returning to their home country for their senior year internship. Student Zhang Mei-hua (張美花) noted: “Using solar thermal energy to dry agricultural products can help farmers increase their income.”

The students sought advice from solar energy expert Dr. Zhang Wen-qu (張文曲) for their project. They first designed a patented solar energy collector using vacuum tubes compatible with solar water heaters. A solar power generator and a recycled dishwasher completed the main structure of the dryer. (The dishwasher served as a drying box.)

The operational principle of this system is simple. A blower propels cold air from the outside into the vacuum tubes, where it absorbs thermal energy from the sun and warms. The resulting hot air rises naturally into the collection tank above before flowing into the drying box through a pipe to dry the vegetables and fruits. The blower and control system are powered entirely by solar energy.

Compared with sun-drying for long-term preservation, drying in sealed equipment ensures better hygiene and is more efficient. The students carefully moved all the components of their system to the top floor of a school building, assembled them there, and then conducted experiments in the drying box with sliced pineapples, bananas, apples, and other fruit.

“The control system was not optimal at first,” said Bagas, “and sometimes the temperature would be too high or too low. But it was a good learning process for us.” He was responsible for writing the drying system’s AIoT, the remote control program combining artificial intelligence (AI) with the Internet of Things (IoT). He found that when the hot air temperature was too high, the sliced vegetables and fruits would dehydrate quickly and become too hard; if the temperature was too low, they would not dry sufficiently and easily become moldy. Gathering solar energy data presented its own set of challenges: “We recorded every hour of the day, but when it suddenly rained, the data could not be used.”

The team disposed of unsuccessfully-dried vegetables and fruits in the kitchen waste recycling bin. Then they used fresh produce to try again, making necessary corrections and adjustments. After numerous rounds of this process, they finally succeeded. Zhang Mei-hua happily shared, “I recently made dried dragon fruit with our invention. I think it’s quite delicious. What’s best, the nutrition is still there!”

Photos by Cai Yuan-yuan

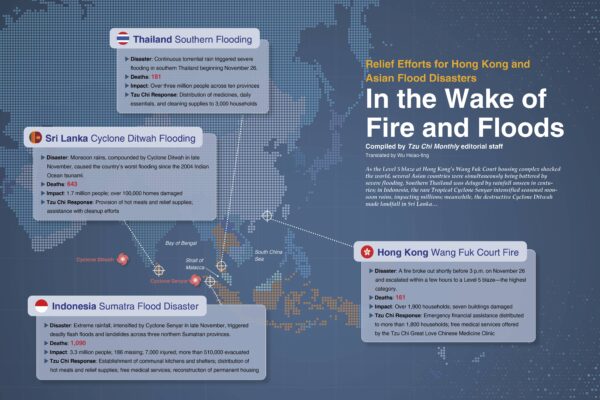

Solar Thermal Energy Automatic Drying System

● Invention Team

Indonesian students from the Department of Business Management at the Tzu Chi University of Science and Technology

● Design

The system consists of three main components: a solar power generator, vacuum tubes, and a drying box. It uses solar thermal energy to heat the air for drying, addressing challenges of produce perishability, limited storage space, and high transportation costs faced by farmers. The dryer’s data is linked to a mobile app for real-time monitoring. This system enhances the value of agricultural products.

Capturing attention

The solar thermal drying system was officially unveiled before summer vacation in 2022, sparking great excitement within the team. The students were based in Hualien when they developed the system, an area with relatively weak sunlight compared to other areas in Taiwan. If the dryer could be effective in Hualien, it would perform even better in Indonesia, with its lower latitudes and stronger sunlight.

According to the data collected by the team, up to 1.9 million tons of chili peppers are discarded annually in Indonesia due to overproduction, which is equivalent to half of its annual production. Processing even one-tenth of the discarded chili peppers into dried peppers could generate a value of 99 million U.S. dollars, comparable to the annual income of 23,000 Indonesian households. Compared to conventional drying processes, this system could save 99 million kilowatt-hours of electricity consumption and reduce carbon emissions by 59,000 tons.

The student team’s innovative creation secured a national patent in Taiwan and won the gold medal in the college green energy innovation category at the 2022 Taiwan Sustainable Energy Creative Implementation Competition. It also garnered the People’s Choice Award and the Special Enterprise Award at the sixth annual Compassionate Technology Innovation Competition held the same year. In October 2023, it won the Silver Award in the Invention Competition at the Taiwan Innotech Expo. The dryer attracted considerable attention from industry professionals during the four-day exposition at the Taipei World Trade Center.

Professor Su Mei-hui (蘇美惠), from the Department of Business Management at the Tzu Chi University of Science and Technology, supervised the drying system project. She said that they had run simulations and found that if they were to dry one ton of produce at a time with their system, they would need to expand it to the size of a shipping container with the vacuum tubes placed on top. Preliminary estimates put the cost of equipment at such a scale at about 750,000 Taiwanese dollars (US$23,600). “According to calculations based on Indonesia’s sunlight conditions, excluding the rainy season, it would take only about 1.7 years to recover the cost,” remarked the professor. She mentioned that during the Taiwan Innotech Expo, a ranch owner from China’s Gansu Province who raised horses suggested that if their equipment could be scaled up to dry a large amount of grass at once, it would more efficiently help people like him store the hay needed for their horses to survive the winter.

Dr. Zhang Wen-qu, the solar energy expert, said that he had learned from people in the petrochemical industry that the toxic sludge produced during oil production is typically dried using electric heating. If solar thermal energy could be used for drying instead, it could save hundreds of millions of dollars in energy costs. “There are many industrial processes that require heat energy. The students’ design could be adapted for more applications by manufacturers,” Zhang said optimistically.

Professor Su further analyzed: “In the past, manufacturers used the most easily accessible and low-cost fuel, coal. However, there is now pressure to reduce carbon emissions, and carbon will be priced in the future. Therefore, they must find clean energy sources to replace it.” In this context, the Solar Thermal Energy Automatic Drying System has a promising future.

The research and development process of the drying system was a valuable experience for the student team. Bagas, for example, demonstrated his strength by designing the AIoT remote control program for the system, which played a significant role in his admission to the prestigious Tsing Hua University in Taiwan for graduate school.

Having gone through the arduous journey of research and development, the young students featured in this article have not only increased their aptitude for problem-solving but also demonstrated creativity in protecting the Earth and practicing environmental sustainability.