By Chen Shi-hui

Abridged and translated by Wu Hsiao-ting

Photos by Alberto Buzzola

Used with permission of Rhythms Monthly magazine

This is a story of a blacksmith from an impoverished background who won respect and admiration for his work by dint of his incessant efforts and an unflinching pursuit for excellence and perfection.

“

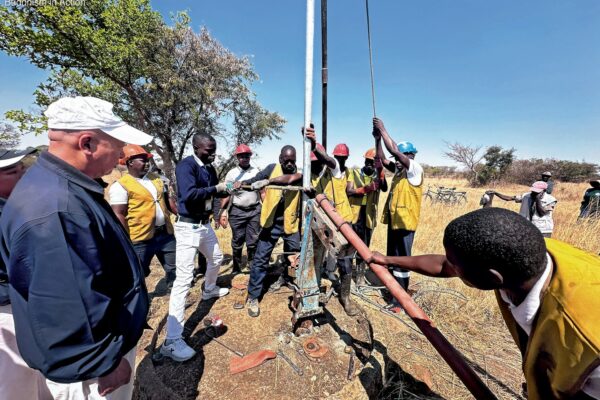

Be sure that the two pieces fit evenly together so that the place where they connect won’t curve inward,” said a swarthy, squat man as he inspected the craftsmanship of one worker after another in an ironworks in New Taipei City, northern Taiwan. His voice was neither sonorous nor demanding, but because he could always pinpoint the flaws of a work-in-progress, everyone in the factory followed his directions without protest.

The turnover rate for blacksmiths is relatively high, but this ironworks is an exception. The owner, Zeng Wen-chang (曾文昌)—the swarthy, squat man—is the reason why.

Chen Yu-jia (陳育嘉), 24, is one of the blacksmiths employed at the workshop. His family owns an ironworks, but he had no interest in blacksmithing or taking over his family business until, on the eve of his graduation from university, he chanced upon some works Zeng had posted on Facebook. “Wow,” Chen thought, looking at the photos. “How is it possible for him to take an ordinary staircase and turn it into a work of art?”

With his father’s permission, Chen applied for a job at Zeng’s factory before he had even completed his compulsory military service. As soon as he was discharged from the military, he reported to work at the ironworks. He was among those mentioned at the beginning of this article whose work was being inspected by Zeng. Zeng had asked him to take apart and redo something he had just soldered together. Despite being critiqued for his workmanship, Chen wasn’t in the least bothered. In fact, just the opposite: he savored working under Zeng and learning from him.

Liu Qi-yang (劉啟暘), 25, is another young craftsman in the workshop. He is a creative person, whether he is playing guitar, performing with his band, or making something with his hands. Zeng thinks he has a natural talent for blacksmithing, but like many creative people, he has quite a temper too. One time he was caught red-handed skipping the standard operating procedure prescribed by Zeng. The young man felt so humiliated he quit on the spot.

Two weeks later, however, Liu swallowed his pride and asked to be taken back. He had already landed a new job, but he couldn’t bear working there. “My new boss approved of everything I made,” he explained. “But I knew full well that none of it would ever pass muster with Boss Zeng.” Zeng is quite a perfectionist, and Liu had obviously acquired the same high standards. For Liu, working for someone less discerning just wouldn’t do.

Everyone who knows Zeng knows him to be hard-working, thoughtfully attentive to detail, and bent on pursuing the best. Mrs. Xie was one of his clients. Zeng’s workmanship can be seen throughout her house in Hsinchu, northern Taiwan, from the outdoor parking space, the wrought-iron fence around the front yard, the hanging staircase in the living room, and the book case in the study. “We never had to oversee Zeng’s work while he was at it because he always demanded more of himself than we did of him.”

Mrs. Xie recounted how Zeng would first make a piece and then make repeated adjustments until everything fit perfectly, and how his creations were sturdy and strong without sacrificing aesthetic appeal. When it came to dealing with the arch-enemy of metals—moisture—Zeng shunned the easy solution of using water-proof paint, like many others did. “Instead, after making sure everything fit perfectly and worked well, he’d have the entire assembly—I mean the entire piece,” Mrs. Xie repeated for emphasis, “sent in for galvanizing. This was to prevent rust from starting in places like the screws, thus thwarting future hard-to-fix leaks before they could form.”

Word spread through the grapevine of Zeng’s fine craftsmanship and his conscientious pursuit of quality. As his reputation grew, so did the line of people that wanted to order his creations. Once in a single neighborhood, more than ten house owners were queuing for his services. They were willing to wait as long as nearly two years—an indication of the craftsmanship he offers.

Everyone who has worked with him, including homeowners, interior designers, contractors, and government workers, has nothing but accolades for him. When asked why everyone raves about his work attitude and the quality he delivers, he said shyly, “I’m just an ordinary metal worker—it’s just that I take my work very seriously.”

Welding is a basic blacksmithing skill. A good metal worker can, with an excellent control of temperature and timing, create a piece that bears few or no welding marks.

Inconspicuous

If you have ever had your house decorated or renovated, you might remember employing the service of a mason, a carpenter, a plumber, or an electrician. But have you ever encountered a blacksmith? More often than not, the response to this question will be a blank stare in return.

Compared with the other related trade workers mentioned above, the role of an ironsmith in the field of interior decoration seems a lot less conspicuous. This might have to do with the comparatively low percentage of iron materials used in interior decoration. “Besides, to be honest, the work of a blacksmith is also more dangerous than that of the other kinds of workers,” said Zeng. “The material we work with is heavy and cumbersome. We can easily get crushed moving things around. The risk of burn injuries from welding is high too. That’s why we often feel that our work is the roughest and toughest among all workers in the construction trades.”

Given the seeming “unattractiveness” of the work, why did he become a blacksmith in the first place?

Zeng is where he is today because of his impoverished background. He said that his family was so destitute that he was already borrowing money as an elementary school student on behalf of his mother to keep his family going. Later, when an older relative got him a job at an ironworks factory, Zeng went for it, feeling that he didn’t have much of a choice.

When he first started and was still getting familiar with the tools he had to use, he’d often burn his face when using a welder, leaving behind patch after patch of frightening pink flesh. But he kept at it, and never gave up. One time, he even fell off a sheet metal roof that he was working on. He hit his head hard and was knocked unconscious on the spot. He still gets dizzy spells as an aftereffect from that fall.

Thankfully, those hard days are now behind him. Building countless sheet metal structures and installing innumerable steel doors has taught him the solid skills required of an excellent ironworker. His days of apprenticeship long past, he’s come into his own as a master blacksmith and set up a shop of his own.

For a long time, there wasn’t much of a demand in Taiwan for his superior skills and workmanship. Before the 1970s, hand-forged wrought-iron windows noted for their decorative appeal could often be seen in the countryside and urban areas of Taiwan. However, when Taiwan’s economy began to take off in the 1970s, the ironworks were gradually replaced by standardized, mass-produced metal windows and doors that were better at deterring burglars. Even though Zeng was eager to try his hand at commissions that could allow his skills and creativity to come to full play, such opportunities were hard to come by.

The pendulum began to swing back a couple of decades later when the industrial style began to gain popularity in Taiwan’s interior design circles. Many ironworkers started to get commissions for things other than traditional doors, windows, and sheet metal buildings. To a certain extent, Zeng had been preparing for this day for a long time. The spring of his life had finally come.

Hot-dip galvanizing is a technology often employed in advanced countries to prevent corrosion and rust in an iron or steel piece. Xiao Sheng-yan (蕭勝彥), who owns a galvanizing plant, says that only people like Zeng Wen-chang, who put a premium on the quality of their work, have their entire pieces of finished metal work processed with hot-dip galvanizing.

Taking wing

With the popularity of the industrial style, “the variety of stuff we can try our hand at has become a lot richer,” Zeng said. “Take staircases, which have become sort of a signature of my team. There are L-shaped staircases, hanging staircases, spiral, and so on. Each kind is different and brings new challenges.” Zeng began to gain fame in his field after successfully completing a few commissions that others felt were beyond their ability and had not dared take on. Increasingly, designers sought him out to transform their wilder ideas into reality.

Interior designer Lin Yin-you (林殷右) has known Zeng for over a decade. He said that because of Zeng’s demand for precision, “he always recalculates the measurements we provide him. He carefully deliberates on all the load-bearing elements of a structure, too. More importantly, he is good at balancing a designer’s imagination and sensibility with his rationality and practicality. But what makes me admire him the most is that when he encounters designs that are more unusual, he never responds with: ‘This is impractical. The idea is impossible to carry out!’ Instead, he’ll think hard on how to make things work. He regards every assignment as an opportunity to explore his creativity.” Out of admiration for him, Lin said, some of his associates in the design circles secretly call him “Iron God.”

If the popularity of the industrial style in Taiwan allowed Zeng to break the mold of a traditional blacksmith and gave him the opportunity to explore a new world, the Internet has given him wings with which he’s soared.

Zeng set up his first-ever blog with a friend’s help more than ten years ago. Keeping it up to date was natural for him. He had started keeping a daily work journal as an apprentice, in which he’d record what he was learning and feeling. With the launch of his blog, all he needed was to transfer his practice from pen and paper to digital. The blog brought him and his works to the attention of many people. People who needed the services of an ironworker began contacting him directly or telling their designers that they wanted Zeng to craft their metal pieces.

“Traditionally, most of the clientele of an ironworks are passersby,” Zeng explained. “Only a small percentage comes through references from designers. But the Internet has opened a door through which we can establish direct contact with the market.” Surprisingly, though the opportunities for a blacksmith to demonstrate his skills have become richer, Zeng said one doesn’t necessarily make more money from commissions for furniture or designer items than for iron windows and sheet metal buildings. The designer work requires more hours and extra work, especially if a blacksmith has a high demand for quality. Many blacksmiths have therefore gone back to making sheet metal buildings where they can make money more quickly.

A project Zeng’s workshop was working on during the writing of this article serves as a prime example. The project was a bus stop shelter in the shape of a whale’s tail. Due to budget constraints, the designer’s original plan was to make the tail partly of tempered glass and partly of braided steel strips. But after Zeng saw the design, he blurted out: “Wouldn’t it be better to make it entirely of braided steel strips? The end product would look so much better.” As soon as the words were out of his mouth, he realized he’d have to absorb the additional costs if his suggestion was taken. But even so, he didn’t regret making the suggestion. In the end, the designer adopted his design, and he had to absorb the additional costs.

Another example was a commission for the entrance gate at Sinpu Elementary School in New Taipei City. Sinpu is a public school and had a limited budget for the gate. They settled for a gate they could afford, but Zeng increased the thickness of some of the steel plates in the door to make the gate sturdier and better-looking. He made the changes without charging the school any extra money for it. He was willing to sacrifice his profit to deliver the best for the schoolchildren. School principal Li Ming-jie (李明杰) said, “We are really indebted to Boss Zeng. Thanks to him, we now have a gate that is both beautiful and easy to push.”

“My wife is always asking me how come I’m not making much money even though I seem to be so busy,” Zeng said with a wry smile. “I wish things were different too, but I can’t help it. I just keep on doing things that look kind of foolish. There must be a screw loose in me somewhere.”

The Hong family’s living room in northern Taiwan looks livelier because of a slide, custom-made by Zeng and his team.

Metal Pieces That Demonstrate Skilled Workmanship

The creation of refined metal pieces depends on precise measurements and exquisite craftsmanship. Beautiful examples include the hanging staircase (Photo 1), the book case made of iron and wood (Photo 3), and the wrought-iron fence (Photo 2), all of which are Zeng’s handiwork.

The Great Ironworker Age

“In my boss’s mind, there are always things more important than making money,” said Zhang Chao-yu (張朝宇), 35, the second oldest worker at Zeng’s factory. Once an employee at a design company, Zhang has a lot of fun working with Zeng. “He likes to try new things,” Zhang added. “He gets more excited bringing his work to a better, higher level than making money.”

What captures Zhang’s heart even more is that his boss has the good of his employees at heart. Boss Zeng knows that Zhang is not that young any more and that his fiancé lives alone in Changhua, central Taiwan. “Boss Zeng always encourages me to return to my hometown when I’ve learned the requisite skills for being a blacksmith here and set up a shop of my own,” Zhang remarked.

Another employee, Chen Yu-jia, comes from a family that owns an ironworks in Keelung, northern Taiwan. Zeng knows Chen will eventually go back to his hometown and take over his family business there, but he holds nothing back from him. He shares everything he knows with him, just like he does with everyone who works for him.

“He [Zeng] is the reason why I decided to take up and stay in this trade,” Chen Yu-jia declared. In addition to being a good boss, “he set up an unconventional model of success and makes us feel that blacksmithing is a profession we can be proud of.”

Making blacksmithing a profession people can be proud of is a goal Zeng has been working toward for decades. Blacksmithing is not a conventionally glamorous occupation, and some may look down on it as lowly manual labor. Zeng’s mission is to change that. “I believe that no matter the profession,” he said, “one deserves respect as long as one works hard and does his best to cultivate his professional skills and expertise.”

The desire to change society’s traditional perception of ironworkers is a driving force that keeps him improving his workmanship. He has also published a book, the content of which comes from his blog and Facebook page, and has set up a website with other blacksmiths around Taiwan. The website, named “The Great Ironworker Age,” showcases examples of metal work and demonstrates how, with the help of refined craftsmanship, a conventional metal item can be transformed into a work of art.

“We don’t just meet in cyberspace,” Zeng said of the blacksmiths that have joined the website. “We meet in real life too—at dinner parties for example.” Participating blacksmiths invite their wives, children, or girlfriends to the gatherings too. By listening to or taking part in the conversations exchanged during the gatherings, family members get to know the professional side of being a blacksmith. They learn that being a blacksmith is not a low-level job, but a dignified occupation that requires professional skills and knowledge.

The website has entered its second year and now boasts a membership of more than 2,800. It bears witness to how a group of blacksmiths are forging a path for themselves and creating a “Great Ironworker Age.” Zeng, a major player behind the movement, is happy to see it. In the company of his fellow blacksmiths, he will continue on, seeking to improve his skills, in pursuit of his best work, and to advance the profession for future blacksmiths in Taiwan.

Zeng crafted the entrance gate of Sinpu Elementary School in Banciao, New Taipei City.