By Yeh Tzu-hao

Edited and translated by Wu Hsiao-ting

Photo courtesy of Wonder Greener

Since its establishment in 2020, Wonder Greener has sold 50 million eco-friendly straws globally—each offsetting around 0.6 grams of carbon emissions.

Bulrush stems, typically 0.6 to 0.8 centimeters (0.24–0.31 inches) in diameter, are turned into natural drinking straws through simple processing and drying. These eco-friendly alternatives reduce environmental impact and have helped establish Wonder Greener as a sustainability-driven social enterprise.

“

Over two trillion drinking straws are used worldwide each year,” said Benson Chen (陳柏燊), co-founder of Wonder Greener, one of the teams selected for the fifth year of Tzu Chi’s Vision Future Incubator. “That amounts to more than 1.6 million tons of plastic. So, we developed a sustainable alternative: straws made directly from plants. After use, they can go into general waste or food scrap bins, and even if incinerated, they won’t release harmful substances.”

Chen’s interest in eco-friendly straws began even before Taiwan’s Environmental Protection Administration (now the Ministry of Environment) introduced restrictions on plastic straws in 2019. He was operating five or six restaurants and cafés at the time and had been searching for non-plastic alternatives to use in his stores as a way to help the environment. Stainless steel and glass straws raised hygiene concerns, while disposable paper straws softened too quickly—all of which failed to resonate with customers. Then he came across a news report from Vietnam about straws made from bulrush—a wetland plant with tall, hollow stems—and his curiosity was piqued. He shared the article with a friend knowledgeable about aquatic plants, and in 2018, the two traveled to Vietnam to learn more.

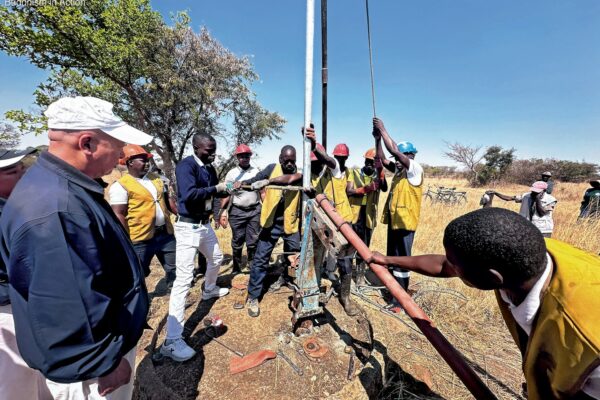

Chen had assumed bulrush straws were widely available in Vietnam. But after visiting more than 200 food and beverage establishments, he found only one that actually used them. This eventually led him to a field of bulrushes and a processing workshop along the Mekong River. There, he observed a simple production process: rural women cut harvested bulrush stems to customer-specified lengths, cleaned out the hollow centers with basic tools, then washed and packed the finished straws for delivery.

“I wanted to buy some to use in Taiwan, so I asked them to sun-dry a batch for me,” Chen recalled. “After trying them out, I realized they were really practical.” The straws resisted soaking and were compostable on land and in water, making them a truly eco-friendly alternative to plastic. And while both plastic and paper straws generate carbon emissions, each bulrush straw has a negative carbon footprint of around −0.6 grams, supporting broader climate action goals.

However, cost posed a major hurdle. Each bulrush straw cost four New Taiwan dollars (US$0.13), compared to one NT dollar for paper straws and just 0.10 NT dollars for plastic. Chen realized he needed to scale up and mechanize production to bring prices down and make them viable for mass adoption, so he established a processing plant in Vietnam and expanded bulrush cultivation. In 2020, he and like-minded partners officially launched Wonder Greener, setting out on a dual path of social enterprise alongside his restaurant and café business. Thanks to the team’s research and development, the cost per straw has since dropped to just 0.60 NT dollars.

The benefits of bulrush extend well beyond reducing plastic waste and carbon emissions. Because Wonder Greener avoids pesticides, its fields teem with snails, shellfish, insects, and fish, creating a habitat that attracts birds and mammals and fosters a vibrant, balanced ecosystem. Economically, bulrush cultivation provides stable income and employment opportunities for rural communities.

As global awareness of sustainability grows, so does the demand for alternatives to plastic. Wonder Greener’s straws are now used by Taiwan High Speed Rail and a Hong Kong coffee chain, with over 800 businesses placing regular orders. Chen’s company is not only growing and processing bulrush in Vietnam for global markets but is now cultivating native bulrush in Taiwan in preparation for future mass “Made in Taiwan” production.

Despite their youthful energy and drive, Chen and his team initially lacked experience in areas like funding and business development. He candidly admitted that their main reason for applying to Tzu Chi’s 2021 Vision Future Incubator was to secure operational funding.

“We had just started promoting our product in Taiwan at the time and didn’t have much visibility,” he said. “I thought Tzu Chi might be more receptive to our mission.” The move proved fruitful: in addition to winning a grant, the team also gained valuable mentorship and networking opportunities.

“We were given guidance on sales and marketing strategies and received support in determining where to begin,” said Chen. He appreciated the structure of the program, which required a clear plan for using funds and progress reports, a valuable training experience for the team.

Still, Chen stressed that while grants can be helpful, they’re only part of the journey. “They make things a bit easier—they give you a short break from financial worries,” he said. “But ultimately, you have to chart your own course and build a sustainable business model. Making it work takes relentless effort.”