By Chen Li-an

Abridged and translated by Wu Hsiao-ting

Photos by Hsiao Yiu-hwa

A Tzu Chi volunteer tells victims of Typhoon Haiyan during an aid distribution in the Philippines that the blankets they will receive were made from recycled PET bottles. The volunteer hopes the message will inspire the victims to cherish the Earth’s resources and recycle reusable garbage to help protect the environment.

Taiwan had achieved a recycling rate of 60 percent by 2017, making it one of the world’s top recycling countries. Despite that impressive record, however, many recyclables still end up in incinerators. Many other countries face the same problem. Some of the items collected for recycling are eventually burned or exported because it is not cost-effective to recycle them.

Take plastic products, for example, which comprise the bulk of garbage that could be recycled. Plastic is made from petroleum, a non-renewable resource that took millions of years to form. It’s a waste of this natural resource when plastic products are thrown away as garbage. “That’s really a pity,” said Marshall Siao (蔡思一), inventor of the Tzu Chi folding bed and the R&D chief at Jing Si Pureland Co., Ltd.

But that’s not the worst of it. Plastics thrown away as garbage do not biodegrade in the environment. They stick around and cause problems long after they’ve been discarded. The Great Pacific Garbage Patch is a prime example. Formed as a result of marine pollution gathered by ocean currents, this “floating junk yard” contains countless polyethylene terephthalate (PET) bottles, other plastic waste, and discarded fishing nets. A study published in Scientific Reports in 2018 put the area of the Great Pacific Garbage Patch at 1.6 million square kilometers (617,763 square miles)—more than twice the size of Texas and three times the size of France.

“Take the plastics eaten by sea birds or fish,” Siao said. “They could be remade into all sorts of different products.” He stressed that discarded products, whether made from plastic or paper, are a valuable resource. Instead of letting them go to waste and becoming a burden on the Earth, it would be more sensible to give them a new lease of life and create a “circular economy,” which emphasizes the sustainable use of resources.

News of animals killed by eating plastic and other waste is shocking and sobering. Marshall Siao, the R&D chief of Jing Si Pureland, uses one such example to illustrate the damage garbage can do to the ecosystem.

From plastic bottles to fabric

Converting waste into high-quality eco-products may be an abstract concept to some people, but techniques to do so have been developed in many industries. In Taiwan, a well-known example is the transformation of recycled PET bottles into fabric. One of the most famous products of DA.AI Technology, a social enterprise founded in 2008 by some entrepreneurs who share Tzu Chi ideals, has been blankets made a hundred percent from recycled PET bottles.

Working with more than 150 manufacturers, DA.AI Technology has developed a great variety of products using fibers extracted from used plastic bottles. Such products include men’s suits, baby and children’s clothing, and uniforms worn by Tzu Chi volunteers on disaster relief trips. They’ve even produced backpacks, carrying bags, and shoes made partly of such recycled fibers.

Visitors to DA.AI Technology’s website can see how many PET bottles are used to make each eco-friendly product and, compared with polyester fiber made from virgin materials, how much petroleum and water is saved in the production process. The amount of carbon emissions avoided for each item is also available. The company donates all its profits to the Tzu Chi Foundation to help it carry out its charitable work globally.

Some people shun products made from recycled materials because they associate garbage with filth, but according to Li Ding-ming (李鼎銘), the executive director of DA.AI Technology, to manufacture high-quality yarn from recycled PET bottles, they have to make sure their raw materials are very clean and pure. Impurities in the recycling process foul things up and result in threads that break more easily.

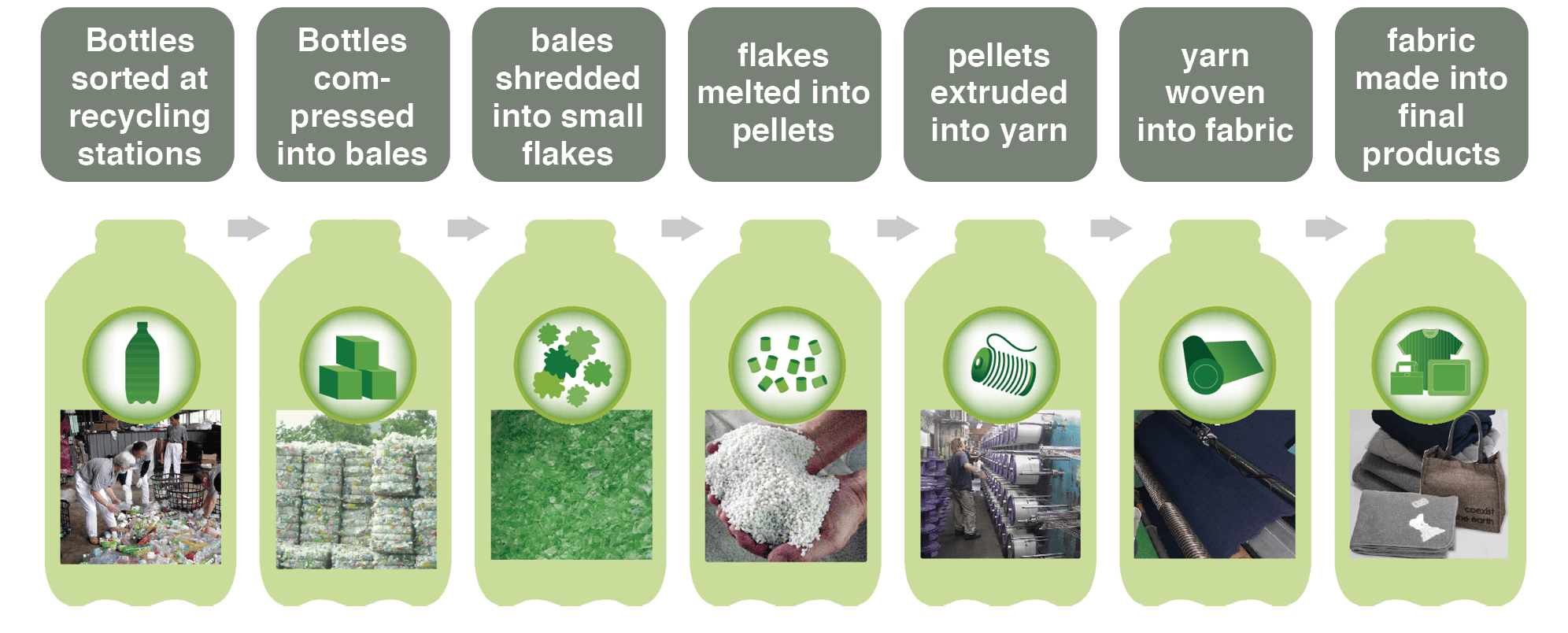

In 2019 alone, DA.AI Technology purchased more than 1,700 metric tons (1,875 tons) of PET bottles from Tzu Chi recycling stations for processing into fibers. These bottles had all been thoroughly sorted, de-capped, and de-ringed by Tzu Chi volunteers. The bottles were then transported to factories where they were shredded, washed, melted, and extruded into yarn to be made into final products. DA.AI Technology applies for the MIT (Made in Taiwan) Smile Logo for each product it makes. This government certification assures the quality of a product, and proves it has passed rigorous testing and is safe for human use.

In addition to transforming PET bottles into fabric, DA.AI Technology has developed other products too. For example, they’ve produced safety goggles and face shields from recycled materials in response to the coronavirus pandemic and provided them for the use of front-line workers. Its current focus is on how to reuse PET and polypropylene (PP) plastic waste. They are continually striving to develop a wider offering of higher value-added products from the many waste materials reclaimed at Tzu Chi recycling stations. Not only will such products be valuable in helping to conserve the Earth’s resources, but they can also ameliorate the huge impact of waste on the environment.

Volunteers at a recycling station remove rings and caps from PET bottles and sort the bottles by color for recycling. Rings and caps are usually made of different materials from the bottles and need to be removed to allow the bottles to be converted into quality yarn.

The conversion of PET bottles into textile products

The recycling of paper containers

The potential of trash is unlimited. Products developed from it can be as varied as blankets, suitcases, shoes, and even construction materials. After working on it for two years, Marshall Siao, the aforementioned Jing Si Pureland R&D chief, successfully produced paving bricks from the plastic linings inside discarded paper containers. An outdoor space on the third floor of a Hualien Tzu Chi Hospital building was paved with more than 6,600 such bricks. The non-slip patterns on the surface of the bricks are in the shape of palm prints, which symbolize the hands that have made the recycling of waste plastics into paving bricks possible.

Siao was a Tzu Chi representative and observer at the United Nations Climate Change Conference in 2019. He was astounded to learn at the conference that the economic cost of air pollution is ten times that of World War II. Most people think that paper containers are environmentally friendly because they are made of paper and recyclable, but they contribute to air pollution too.

According to Taiwan’s Ministry of Economic Affairs, close to 6,600 million paper containers were sold in Taiwan in 2018. This is staggering, but the number doesn’t even include those whose sale wasn’t reported to the Ministry. If paper containers produced by underground factories are also factored in, the estimated total number comes to 8,000 million. Because most of these containers were soiled with grease or other stuff or contained food waste after they were used, they ended up in incinerators.

Siao explained that paper containers are lined with a thin layer of plastic to make them water-resistant. Typically, 30 to 33 percent of the material used to make a paper container is plastic. Recycled paper containers need to be sent to facilities with the necessary equipment to separate the paper and plastic before they can be turned into reusable raw materials. Taiwan currently has only three companies that have such separation equipment, and then only the reclaimed paper is repurposed. Most of the plastic linings are burned because they are made of mixed plastics, which makes them difficult to recycle.

“How to deal with used paper containers has always been an issue,” Siao said. “No effective solution has been proposed to date.” So to help increase the recycling of paper containers and achieve zero waste, Siao came up with the idea of turning the paper pulp recycled from paper containers into toilet paper and the plastic into paving bricks.

A joint effort among Jing Si Pureland, Cheng Loong Corp., and other companies followed. In this joint undertaking, Cheng Loong Corp., a company principally engaged in the manufacture of paper products, provides plastic linings separated from paper containers for partner factories. The plastic linings, such as those from meal boxes and cups, are then made into paving bricks that have a high degree of permeability and can bear a weight of up to 40 metric tons (44 tons).

Siao explained that 1.7 kilograms (3.7 pounds) of waste plastic is needed to make a paving brick. This is equivalent to the amount separated from 350 meal boxes or cups. As mentioned above, more than 6,600 such paving bricks were used to pave the outdoor space on the third floor of a Hualien Tzu Chi Hospital building. The bricks—6,602 to be exact—were made from the recycled plastic of 2.31 million paper containers. Their production can be further translated into a reduction of 11.7 metric tons of carbon emissions. Using recycled materials to make bricks can also reduce the mining of sand and gravel. “What we hope most of all by converting waste materials into usable things is to lessen damage to the environment,” Siao reiterated.

As for the paper pulp recycled from paper containers, Cheng Loong makes it into toilet paper and packaging paper. A hundred metric tons of recycled paper can be made into 60 metric tons of toilet paper, which can save more than 2,000 trees from being felled. Cai Shi-yu (蔡石玉), director of one of Cheng Loong’s factories, said that his company converts recycled paper pulp that is “cleaner” (uncontaminated by grease) into toilet paper because customers in Taiwan like their toilet paper pure white. The rest is recycled into packaging paper. Cai added, “Though it is faster, more convenient, and even cheaper to just cut down trees to obtain paper pulp for processing into paper products, it’s less environmentally friendly.”

Cai is happy his company is working with Jing Si Pureland to recycle paper containers. In the past, the waste plastic separated from recycled paper containers at his company was incinerated. Now their joint project with Jing Si Pureland has allowed the separated plastic linings to be made into paving bricks. Though the production process is relatively costly, it’s a good thing for the environment.

Jing Si Pureland has also been actively transforming other kinds of plastic waste into products. Examples include making recycled polystyrene (PS) into bookcases, and converting the inner tubs of discarded washing machines, made of PP, into folding chairs. Siao believes that to achieve zero waste, everyone needs to have correct concepts about recycling, and more importantly, take concrete action to help.

Toilet paper made from recycled paper, such as that obtained from discarded paper containers.

Reducing trumps recycling

The efforts made by Jing Si Pureland and DA.AI Technology in recycling waste into products with a new, purposeful life has one goal: to protect the Earth. Therefore, though the companies make products from recycled materials, they don’t want their takeaway message to be, “continue to use as many plastic products as you want.” As Siao reiterates, if people keep churning out garbage, our environment will never be cleaner—no matter how quickly or efficiently reusable trash is recycled and made into new products. The best way to protect our environment is, like Dharma Master Cheng Yen teaches, to cherish and conserve everything we have so we can produce as little garbage as possible and help reduce damage to the environment.

Everyone wants to live in a clean, uncontaminated environment. No one wants to breathe polluted air. And yet, we all contribute to the pollution of the world. To pave the way for a cleaner, greener tomorrow, we all need to do our best to lead an eco-friendly life. And we can magnify our impact by motivating others to do the same.

The paving bricks used in an outdoor space on the third floor of a Hualien Tzu Chi Hospital building are made from the plastic linings separated from used paper containers. The durability of these bricks is comparable to those made of concrete. A hundred square meters (1,076 square feet) of such paving bricks can save 20 metric tons of concrete and prevent four metric tons of plastic waste from being burned. LIN BO-YIN